Paraima Opatija – a creative expression of love for swim-wear

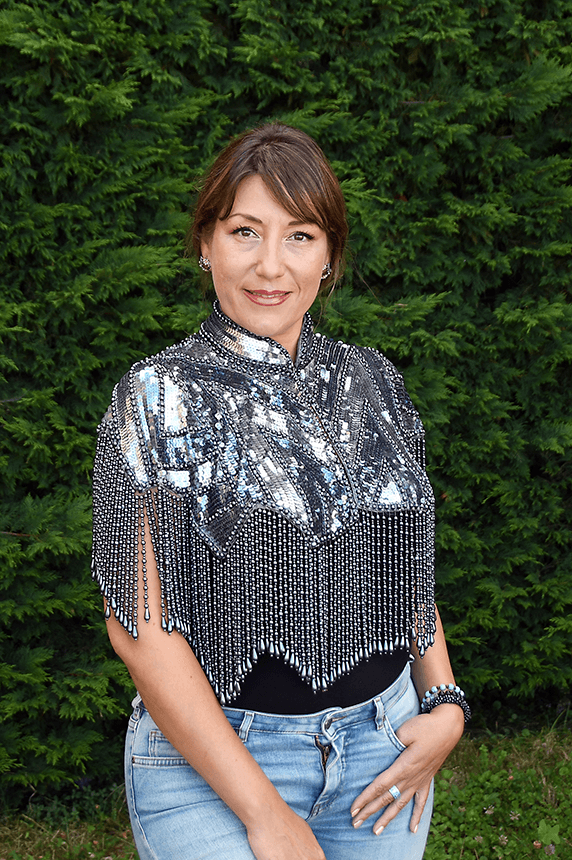

The most important summer outfit is definitely the one for going at the beach, and choosing a summer swimsuit is the most exciting moment in planning your summer vacation. We spoke to Magdalena Šitov, the owner of the Paraima Opatija brand, about her love for this beloved summer essentials item.

Magdalena was born in Poland, raised in Germany and Macedonia, and chose Opatija as her new home out of love. The brand was created as a result of her love for swim-wear, but also the need to express her creativity as a balance toher less creative and demanding profession as a conference interpreter. “The idea was born in 2020, when the pandemic confused us, scared us, took away our jobs, worsened our health, but also made us realize that life is short and we need to gather courage and make at least some of our dreams come true. So I decided to realize my long-standing desire and create a brand that emphasizes European quality, supports family businesses with a long tradition of fair business and uses ecological components with a health safety certificate.”

“As a woman, I love swimsuits, and since I live by the sea, I can never have enough of them! I’ve bought both expensive and cheap, unknown and premium brands, but I always felt that small designers were more dedicated and that it wasn’t all about profit, so I had the need to express myself creatively. Since I realized during the COVID time that my profession has no secure future, I decided to invest everything I have (and don’t have) and embarked on the Opatija Swimsuits project.”

Creating Paraima Opatija swim wear

In designing and creating, Magdalena starts from the material. When she falls in love with a material, she first makes sure that it is suitable for her to consider for the collection, and then she thinks about the design. He likes materials that are ecological, innovative and new on the market, and she doesn’t like it when something is available on every corner. She finds inspiration in various things, and not only from the world of fashion. “The other day I was passing by Torpedo in Rijeka, and there was the inspiration for a swimsuit that has a decoration on the back in gold-white, marble color, let’s say… a somewhat more feminine torpedo…” she explains.

Her biggest challenge is that she designs her collections for women, and women are often taught to hide their bodies. Since every woman is different, not only physically, but also in character, and it is difficult to satisfy all tastes and all body shapes… The process is further complicated by the fact that she does not use wires, due to the possible risks they pose to women’s health, which means that she limits herself to women’s breasts that need little to medium support. “I learned to control my creativity and always think about the women and girls who wear my swimsuits. I don’t plan to put my costumes in a museum, I want to see them on as many satisfied and happy women and girls as possible. Of course, I also make models that will never be produced, but I often want to try to see if something will even be feasible. I like to let myself go and create!”

The process of making a Paraima Opatija swimsuit

“First I collect all the materials I want to use in several colors, test them on myself, throw them in the sea, in the pool, then in the sauna, leave them in the sun for a few days, wash them in the machine at 60° C, drag them around in all directions… The ones that survive become swimsuits. I always have too many ideas, but combining colors, materials and designs is something that steals my sleep at night. And then I put everything on a mannequin and see what it looks like in the morning. A few months later, I choose a few favorites and a few backup options. We designers always have a huge desire to turn our inspiration into reality, and we forget to count the budget, especially when we are self-financed, as in my case. When I finally choose all the components, I move on to the production phase. First, digital models are made, then the first sample, followed by more fittings until the final model is obtained, then it is made in other sizes, and the final fitting is done for all sizes. If everything is in order, production starts in several colors and sizes, labels are sewn and packaged, and they are sent to customers in gift bags.”

Sustainability and health first

Magdalena buys the materials she uses from trusted Italian manufacturers with a long tradition. She uses various materials, including ecological material made from recycled fishing nets, a so-called techno-material that has the ability to contract when dry and relaxes in water, resulting in a slimming effect. And for those who prefer shine, she chooses soft charmeuse that reflects the sun and gives the effect of sand shining in the sun.

All materials have a UV factor of 50, are bi-elastic and super-repellent, meaning they allow water to slide off the skin, which is why they dry quickly. They can be washed at 40°C in the machine, which is rare for swimwear. The components used are made of Italian-made Plexiglas. The bikini top pads are made in the EU from 100% organic cotton, and the sanitary pads are made in Rijeka. The components and materials are hypoallergenic, do not change color or shape, and are resistant to sun, chlorine, salt water and sunscreens/oils.

“Sustainability plays a big role in the choice of materials, and on several levels. One is the ecological side, where we do our best to find beautiful ecological materials that do not pollute the environment even in the dyeing process itself. The other side is the procurement of components and materials made in the EU, which reduces our transport routes, and thus our CO2 footprint. Regarding the design, we come up with various ways that one swimsuit can be worn in several ways, tied differently, or styled on the fly. Mix and match option of combining bikinis helps to make more combinations with few pieces, and to be worn as a top in summer outfits. When it comes to design, I’m also thinking about leaving as little surplus as possible in production, and using what’s left for laces and pendants. The ethical side is also very important to us, which is why we carefully choose who we work with. We have zero tolerance for poor working conditions, exploitation of workers, child labor, inhumane working conditions, which is why we favor family companies with a long tradition. Unfortunately, these circumstances are current in the fashion business with rulings due to poor working conditions for Valentino and Dior bags. Sanctions have been issued for factories in Milan, but the brands are pretending that nothing happened.”

Challenges and the future

“Creating a boutique brand is one of the riskiest financial ventures, given that the brand owners invest their time, energy, money and creativity, and has no idea if they will sell it or if they will be able to finance the next collection,” Magdalena tells us.

Despite all the challenges, she plans a transitional collection at the end of 2025, a bit heavier, more pompous and luxurious in terms of components, but still limited in pieces. Dresses and kimonos will still be part of the collections, and with a bit of luck in 2026 she will also embark on a project of an organic perfumed suntan oil, which could become a reality.

Magdalena’s favorite: Lovran Love bikini in Chocolate Dream.

“The only one in the world with a” chocolate cube “that can move so that the top part shows more or less skin and adapts to the breasts of every girl and woman. The bottom part of the bikini is a mid-rise cheeky panties with blind seams, which cover everything you need and are not felt on the skin at all. It dries in literally five minutes 😉”